Challenge

VCST struggled with slow, manual reporting processes across its global branches. Data was collected centrally in Belgium, but the analysis and sharing involved multiple steps and delays which impacted communication and decision-making.

Solution

ACA developed a centralized, user-friendly reporting tool, allowing all branches to access real-time production data and quality reports. A global dashboard provided the Belgian headquarters with an overview of all sites.

Result

The new system automated data analysis, reducing manual effort and delays. Real-time access to reports improved decision-making, while increased collaboration across branches led to a more efficient workflow and better quality control.

About VCST

VCST is an international automotive supplier that specializes in powertrain and brake components. With branches in Belgium, Germany, Romania, China, and Mexico, the company is known for producing high-quality gears for the automotive industry.

Challenge

Optimizing data analysis across multiple sites

Previously, VCST had a prototype reporting tool for its Belgian branch, developed by an engineer. This tool allowed employees to request analysis on production quality for gears at their location. However, with VCST operating across multiple countries, the process of collecting, analyzing, and sharing this data was inefficient.

- Previously, VCST had a prototype reporting tool for its Belgian branch, developed by an engineer. This tool allowed employees to request analysis on production quality for gears at their location. However, with VCST operating across multiple countries, the process of collecting, analyzing, and sharing this data was inefficient.

- Data had to be manually sent back and forth, creating delays and inefficiencies.

- Communication across different branches was often slow, affecting response times and the efficiency of quality assessments.

VCST needed a global, user-friendly reporting tool that could improve collaboration and streamline the analysis process for all branches.

Solution

A customized reporting tool for all locations of VCST

After assessing the challenge, VCST turned to ACA for a solution. Our Python development team worked closely with VCST engineers to build a new, robust reporting tool that would be accessible across all branches.

We created an admin panel that centralized analysis and reporting for all production sites.

The tool allowed each branch to access its own analyses and reports instantly.

The main Belgian branch could monitor and evaluate quality results from all locations in real-time.

The new system improved communication, shortened lead times, and allowed for better tracking of production quality across the globe.

Result

Increased efficiency and automation

The Python-based reporting tool brought significant improvements:

- Shortened lead times: Data analysis and report generation became much faster, as reports were available instantly for all branches.

- Increased automation: The tool automated the reporting process, reducing manual intervention and human error.

- Improved collaboration: All branches could easily access and analyze production data, leading to better communication and faster decision-making.

- Enhanced traceability: Reports were structured consistently, ensuring stakeholders from all sites could easily interpret results.

Overall, the new tool provided a reliable, scalable solution that improved the efficiency of VCST’s global operations.

With the help of ACA, VCST can perform uniform analyzes worldwide on key gear quality measurements. The reporting software developed significantly shortens the lead time for these analyses, from a few days to a few hours. We are very satisfied with the cooperation and approach of ACA!

former R&D Manager at VCST

With the help of ACA, VCST can perform uniform analyzes worldwide on key gear quality measurements. The reporting software developed significantly shortens the lead time for these analyses, from a few days to a few hours. We are very satisfied with the cooperation and approach of ACA!

Looking to streamline your reporting processes and improve global collaboration?

Looking to streamline your reporting processes and improve global collaboration?

Looking to streamline your reporting processes and improve global collaboration?

Looking to streamline your reporting processes and improve global collaboration?

Related cases

Renson partnered with ACA Group to develop user-friendly apps for controlling patio covers, shading, lights, heaters, and air quality systems. Overcoming diverse hardware and network challenges, ACA delivered seamless solutions, including a rapid two-week rollout of CO\u2082 monitoring features during the pandemic.

Stad Hasselt is undergoing a digital transformation to bring city services closer to their residents. To ensure the mobile app was intuitive and user-friendly, we conducted expert UX reviews and real-world user testing. The result? A highly rated city app that makes accessing services easier than ever.

To improve its customer journey and online presence, Attentia partnered with ACA Group to create a future-proof website. By replacing multiple fragmented platforms into one website, Attentia optimized their #OneAttentia experience. Customers can now easily access the right services while enjoying increased efficiency, stronger branding, and greater engagement.

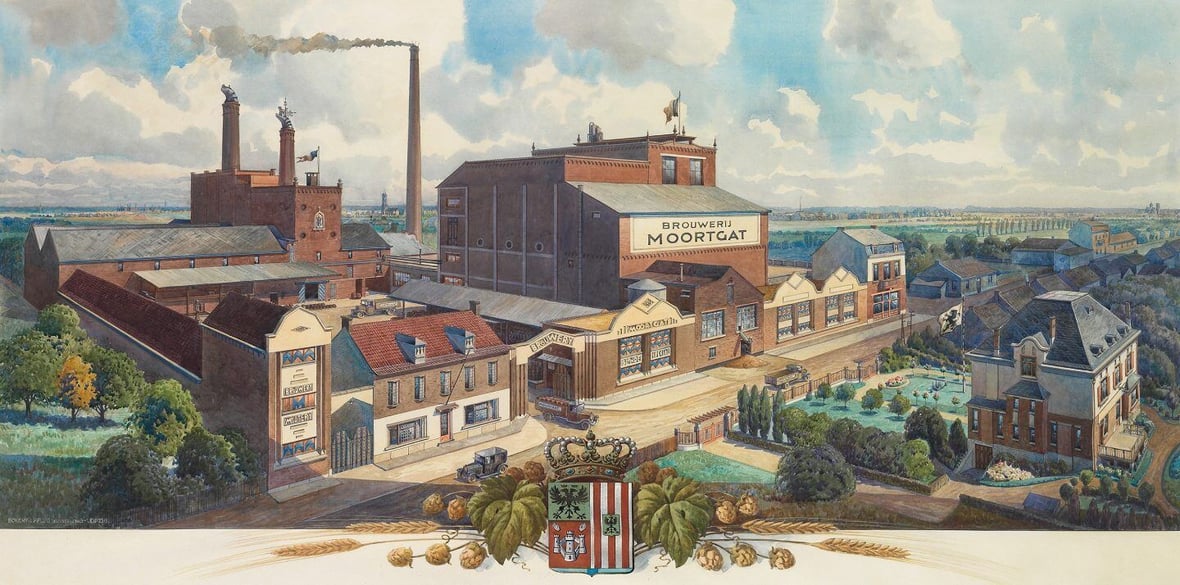

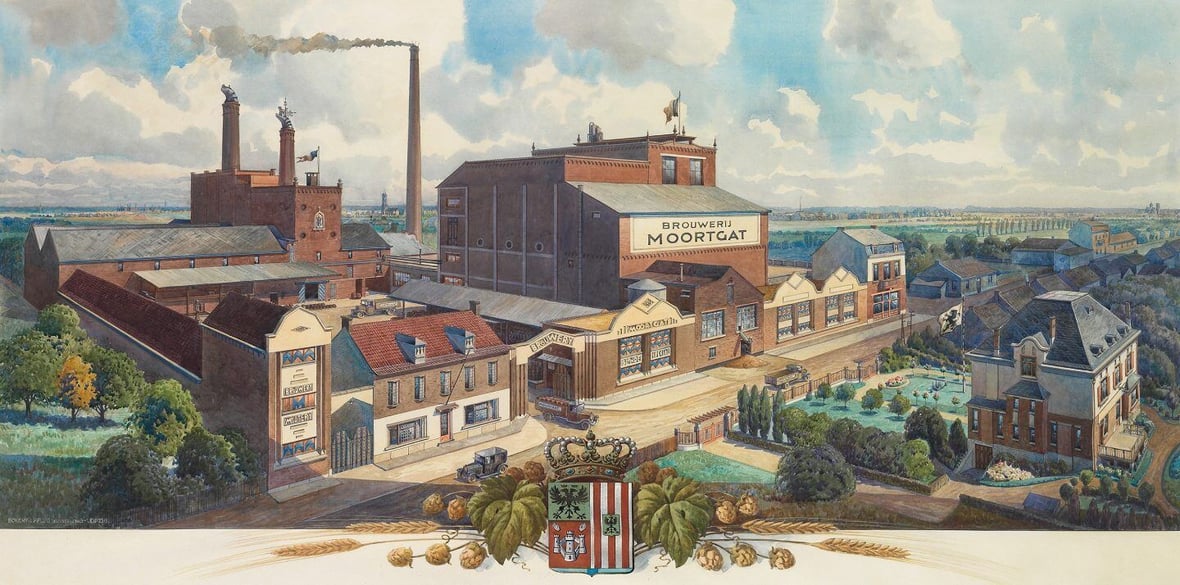

To ensure the safe and efficient transport of their renowned beers, Duvel Moortgat needed a more reliable way to detect damaged pallets. ACA Group developed an AI-powered Computer Vision solution that automatically identifies defects, improving quality control, reducing costs, and increasing operational efficiency. This innovative approach highlights the power of AI in optimizing production processes.

The most rewarding partnerships are those where a supplier actively contributes to a customer’s growth. That’s exactly what ACA Group has been doing with MobilityPlus for over a year. What started as a mobile app for EV charging has evolved into a full digital ecosystem, including a web portal, an Azure data platform, and AI-driven solutions. With ACA’s expertise, MobilityPlus is transforming into a data-driven company, shaping the future of sustainable mobility.

Renson partnered with ACA Group to develop user-friendly apps for controlling patio covers, shading, lights, heaters, and air quality systems. Overcoming diverse hardware and network challenges, ACA delivered seamless solutions, including a rapid two-week rollout of CO\u2082 monitoring features during the pandemic.

Stad Hasselt is undergoing a digital transformation to bring city services closer to their residents. To ensure the mobile app was intuitive and user-friendly, we conducted expert UX reviews and real-world user testing. The result? A highly rated city app that makes accessing services easier than ever.

To improve its customer journey and online presence, Attentia partnered with ACA Group to create a future-proof website. By replacing multiple fragmented platforms into one website, Attentia optimized their #OneAttentia experience. Customers can now easily access the right services while enjoying increased efficiency, stronger branding, and greater engagement.

To ensure the safe and efficient transport of their renowned beers, Duvel Moortgat needed a more reliable way to detect damaged pallets. ACA Group developed an AI-powered Computer Vision solution that automatically identifies defects, improving quality control, reducing costs, and increasing operational efficiency. This innovative approach highlights the power of AI in optimizing production processes.

The most rewarding partnerships are those where a supplier actively contributes to a customer’s growth. That’s exactly what ACA Group has been doing with MobilityPlus for over a year. What started as a mobile app for EV charging has evolved into a full digital ecosystem, including a web portal, an Azure data platform, and AI-driven solutions. With ACA’s expertise, MobilityPlus is transforming into a data-driven company, shaping the future of sustainable mobility.